COMPLETE SOLUTION

KEY MODULE PROCESS OF OPTICAL TRANSCEIVER BONDERS

Our Range of Optical Transceiver Bonders

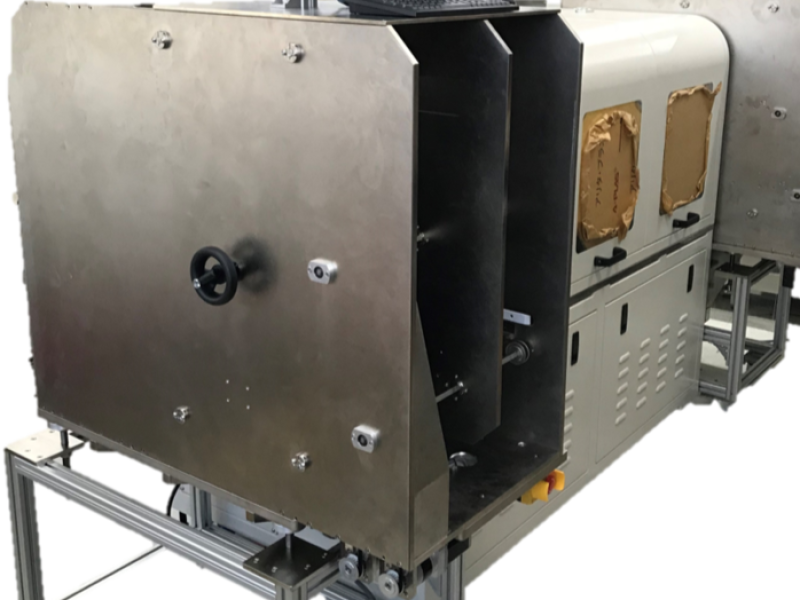

MDA

High Mix Low Volume Semi-Automatic Die & Lens Bonder

- Accuracy down to ±5µm cycle-times down to 30 sec UV cure process

- Eutectic pulse heating soldering or epoxy bonding

- Handle array die

- Closed touch sensing loop bond force control

- Supports all dispensing technologies

- Others: post-bond inspection, heated tools, etc.